About Us

With more than 20 years in the industry, Bio-Dent has built its name as a leader in prosthetic and cosmetic dentistry. As technology evolved and became more integral to the restorative process, we kept pace, adopting new processes and integrating new technology as soon as they were proven effective. Because of this tradition of excellence, we’re constantly integrating the best technologies into our workflow.

To fabricate crowns perfectly accurate to your impressions or files, Bio-Dent’s workflow integrates some of the best dental production capabilities.

Haas OM2 Mill

To fabricate crowns perfectly accurate to your impressions or files, Bio-Dent’s workflow integrates some of the best dental production capabilities.

imes-icore 450i Mill Amann Girrbach Ceramill Motion Mill

With five-axis motion and wet-milling capabilities, our 450i and Motion mills provide us with the accuracy and speed necessary to mill zirconia, e.max® and other monolithic restorative materials.

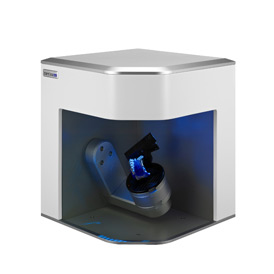

Identica Blue scanner Identica Light scanner Ceramill Map 300 scanner

A great restoration begins with great digitization, and our trio of scanners ensures your models enter our digital workflow accurately and with the resolution necessary to fabricate models that seat accurately with little chairside adjustment.

exocad CAD software Hypermill CAM software Sum3d CAM software

Our CAD/CAM technicians design and fabricate your restorations, bars and abutments using only the most powerful software on the market.